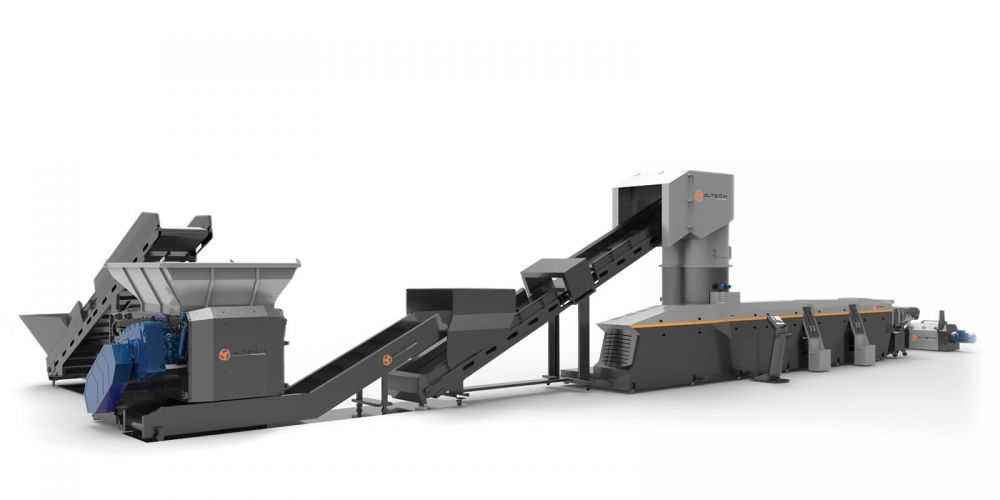

In the applications of hard to break products,PP Big Bag,rigid plastic lumps.This is the connected one another model of the extruder. At first , it crashes and granulates later on.

RGT W –SH Model ,coupled with Shredder,connected with crusher compactor recycling machine, proposes solutions for the hard to crash products:Tough lump,PP Bag,Polyester or PP thread .In this model, in the earlier stage thanks to shredder,crushing is given certain dimensions intensified by crushing compactor and exposed to the extruder phase and finally that is formed as granules.

Shredder and Extruder cooperate each other by transferring data synchronously.

PRODUCTS THAT CAN BE RECYCLED

One shot several products are granulated

High Capacity

Easy Usage

Low Energy Consumption

Specifications:

| Model | RGT W SH 100 | RGT W SH 120 | RGT W SH 140 | RGT W SH 160 |

| Capacitykg/h | 350-450 | 550-700 | 800-1000 | 1000-1500 |

| Shredder (Model) | ALSHR 10 | ALSHR 13 | ALSHR 13 | ALSHR 15 |

| Extruder Screw Diamm | 100 | 120 | 140 | 160 |

| Templastic Material | HDPE, LDPE, PP, SERT TAKOZ PLASTİK | |||

| Ext. Screw Revolutionrpm | 115 | 115 | 110 | 110 |

| Main Motorkw | 90-110 | 132-160 | 200-250 | 315-350 |