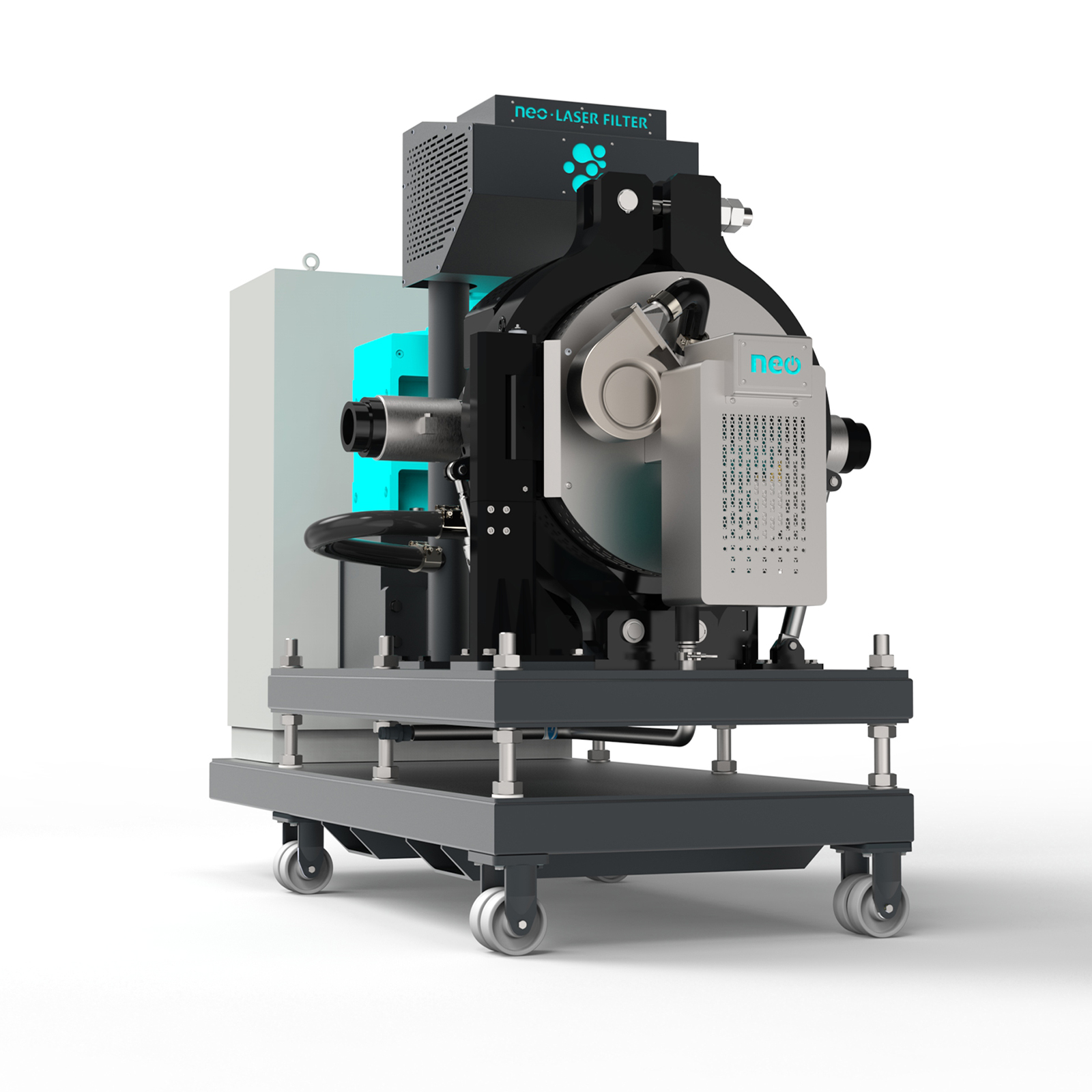

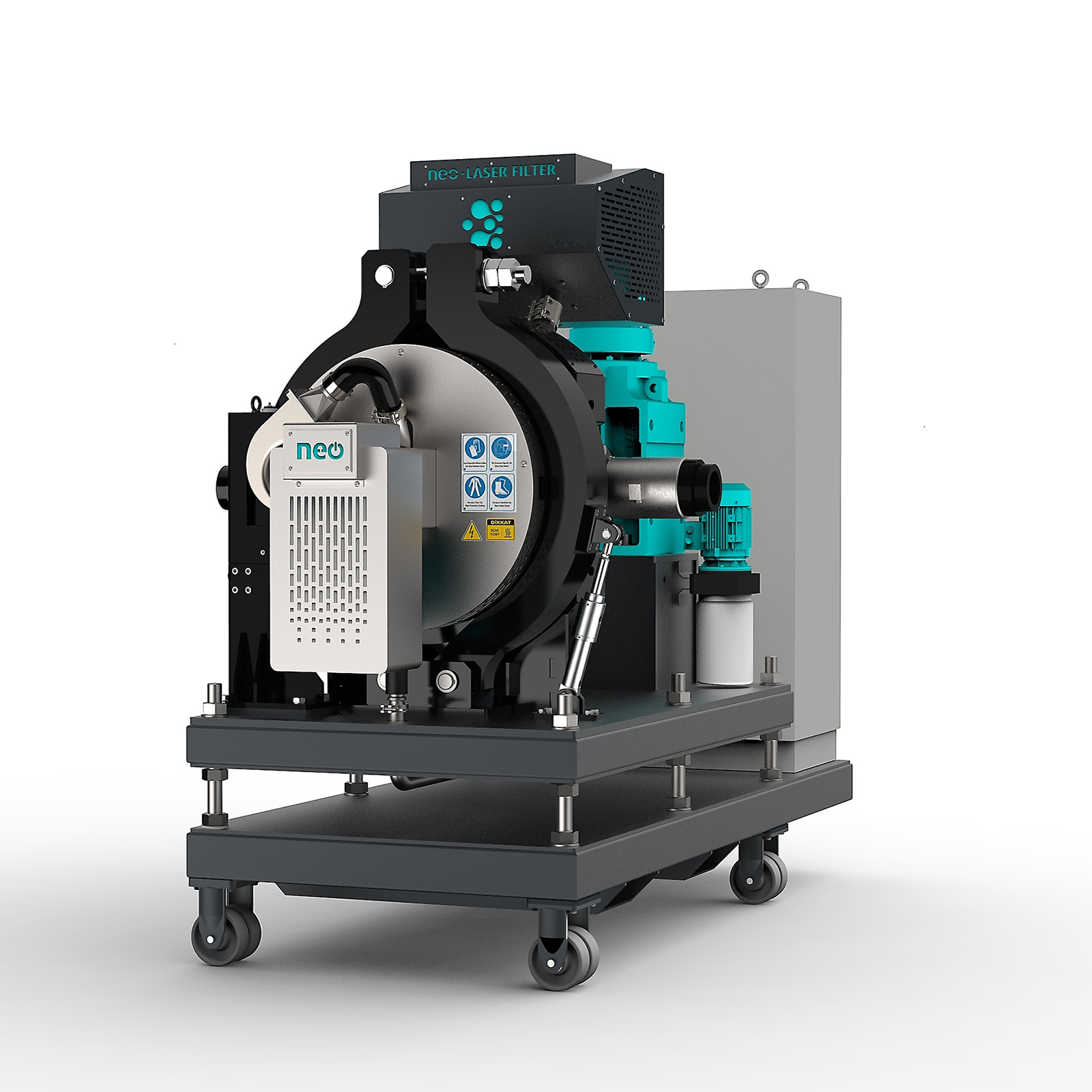

As of December 1, 2025, we provide maximum efficiency, high speed and sustainable power in recycling, thanks to our new Laser Melt Filter engineering and technology.

Paper, rubber, wood, unmelted plastic etc. Unwanted foreign particles such as, with the awareness of its technology, are automatically separated from the plastic without human touch, and their contamination is discharged.

With its high contamination output and low melt loss, the recycling industry provides incredible convenience and profit to manufacturers.

In manual filter systems; In the filtration of industrial paper waste plastics, filter screen changes between 3-5 minutes, with laser disc filter without screen replacement up to 1 week; It provides an excellent performance that allows the extruder to reach maximum capacities.

Altech Laser Melt Filter; designed to be easily connected to all kinds of recycling extruders; It offers models to suit the capacities of customers.

Technical and Economic Advantages

⇒ No more frequent mesh fitler changes!

⇒ No more filter change for the operator!

⇒ Maximum contamination discharge minimum melt loss

⇒ Low melt loss, no more tons of plastic loss per year!

⇒ Perfect clean granule quality

⇒ Increase in product brightness with perfect filtration

⇒ Allowing the extruder to work at maximum efficiency

⇒ Energy saving

Washed Post Consumer (LDPE-LLDPE)

Washed Film (LDPE-LLDPE)

Washed Post Consumer PP Woven

HDPE Regrinds

Excellent Technology and Performance

Possibility of filtration with 150,200,300,350 µm hole diameter

Paper, wood, dust, rubber / silicone polyester, molten particles and black spots from deterioration are removed from the polymer.

İşgücünü bitirir.

Kapasiteyi artırır.

Enerji tasarrufu

Eriyik kaybını minimuma indirir.

| Technical Data | ||

| Filtration Surface Area | cm² | 2450 |

| Disc Diameter | mm | 500 |

| Capacity | kg/h | 700 - 1500 |

| Max. Pressure | bar | 250 |

| Filter Hole Diameter | µm | 150/200/250/300/350 |